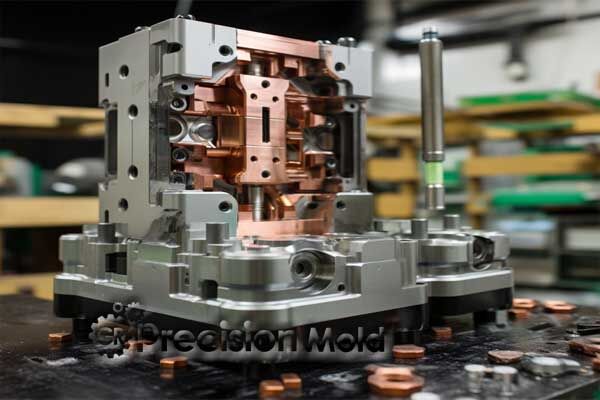

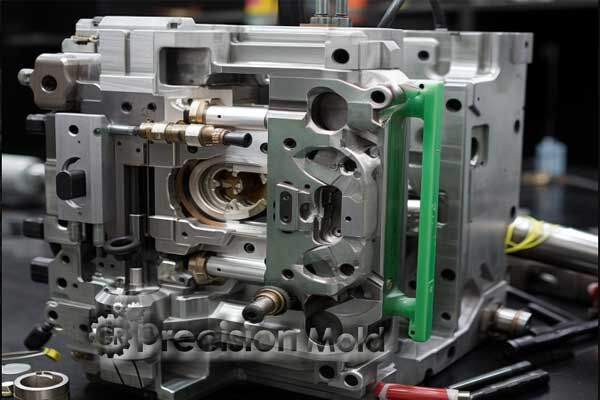

Gallery of Injection Molding Parts

Dive into GRP’s extensive gallery that showcases some of our completed injection molded parts and take confidence that we can create your injection molding project according to your strict specifications.

Experience Innovation in Injection Molding with GRP! Transform your projects with our custom injection molds tailored to your specs. At GRP, we dive deep into your project’s nuances, crafting precise mold designs to ensure success. Let our expert technicians handle all complexities – your success, our commitment!

Unleash the power of versatility with GRP! From prototype tools to production molds, we offer affordability without compromising quality. Our optimized processes and rapid lead times ensure your products hit the market faster. Ready to elevate your plastic part production? GRP is here to guide you every step of the way!

|

|

|

|

Types of Plastic Injection Mold

Dive into a world of options with GRP! We provide a wide range of injection mold tooling to suit your specific needs and applications. From prototype mold tooling to production and export molds, GRP is your trusted ally. Partner with us and experience reliability at its finest!

Prototype ToolingExperience easy design validation with top-notch prototype tooling. Create small batches of plastic parts with excellent injection molding prototypes. We specialize in manufacturing prototype molds swiftly, enabling functional tests and market validation. Our affordable aluminum tooling reduces financial risks before full-scale production |

Volume ToolingWe specialize in crafting top-tier production molds for high-volume plastic parts production. Utilizing durable, high-strength tool steel, our production tooling is apt for hundreds of thousands of parts. We customize materials and methods to your requirements |

2K molds:Unlock precision with GRP’s 2K injection molds. Ideal for two-component molding, ensuring seamless integration of materials in one process. Achieve complexity and superior quality effortlessly. 2K molds:Unlock precision with GRP’s 2K injection molds. Ideal for two-component molding, ensuring seamless integration of materials in one process. Achieve complexity and superior quality effortlessly. |

Inserted Molds: Optimize production with GRP’s inserted injection molds. Designed for embedding inserts into molten plastic, our molds ensure precision, strength, and durability in every part. Enhance functionality and reduce assembly time effortlessly. |

Over Molds: Achieve multi-material parts with GRP’s over injection molds. Expertly designed for molding a layer of material over another, ensuring optimal adhesion, functionality, and aesthetics in a single step. Simplify complex processes effortlessly. |

Gas assist Molds: Maximize efficiency with GRP’s gas assist injection molds. Designed to inject gas into molten plastic, our molds reduce weight, warpage, and sink marks, while enhancing strength and surface finish. Achieve superior quality parts effortlessly. |

|

Single Cavity Mold: Experience precision with GRP’s single cavity injection molds. Designed for producing one component per cycle, our molds ensure consistent quality, optimal cycle times, and cost-efficiency. Ideal for low to medium volume production needs. |

High Precision Tolerance Mold: Achieve unparalleled accuracy with GRP’s high-precision injection molds. Engineered for tight tolerances, our molds ensure consistent, intricate parts with superior surface finish. Ideal for complex, critical applications demanding utmost precision. |

Multi Cavities Injection Molds: Boost productivity with GRP’s multi-cavity injection molds. Engineered for producing multiple parts per cycle, our molds optimize cycle times, reduce costs, and ensure uniform quality across high-volume productions. Ideal for maximizing efficiency. |

Unscrewing Molds: Experience ease with GRP’s unscrewing injection molds. Designed for producing parts with external or internal threads, our molds ensure precision and efficiency in every cycle. Ideal for complex, threaded components demanding high accuracy. |

Why Choose Us for Injection Mold Tooling

|

With eight strategic facilities, we provide full after-sales support in Europe, the US, and Mexico. Expect prompt assembly, rigorous testing, and dedicated follow-up.

|

Over 82% of GRP's staff have remained for over a decade, growing alongside the company. Their loyalty and expertise shape our success and nurture an excellence-driven culture.

|

|

Our Project Managers, former mold makers and designers, bring hands-on expertise. Fluent in English, they ensure clear, streamlined communication, reducing misunderstandings and overheads.

Good Bi-Language Technical Communication Avoid any technical communication mistakes |

Around 86% of our tools sell in Europe and North America, highlighting global appeal and quality. Familiarity with Hasco and DME standards shows our commitment to excellence and smooth client integration in these regions.

|

Injection Mold Precessing

GRP offers custom injection molds tailored to your specs. We employ advanced predictive modeling for quality mold flow analysis, ensuring optimal tooling production. From prototype development to inspection and delivery, count on our expert support.

|

Delivery

|

Instant Quote Request an instant quote and our engineers will deliver it within 24 hours to kickstart production. Fast, efficient, and ready to serve your needs. |

DFM Reports Our design-for-manufacturing review identifies defects or concerns early on, providing recommendations for a more feasible and efficient design. |

Mold Flow Analysis Our predictive modeling software visualizes molten material behavior inside the mold, enabling design improvements for optimal performance. |

|

Mold Building |

T1 Samples Test Post mold tooling, we conduct a trial with a sample mold to ensure accurate dimensions for your required molded parts. Precision guaranteed. |

Engineerigng Change After the first sample, we will address any issues, provide solutions, and make necessary improvements to ensure optimal results. |

Pre-Shipment Inspection We inspect all mold components and packaging before shipping to ensure everything is in perfect order. Your satisfaction, guaranteed. |

Injection Tooling Capabilities

We design and create precise custom injection molds from top-grade materials, ensuring unmatched consistency and repeatability with fast lead times and affordable pricing. All molds meet international standards. Whether it’s a one-off project, small batch, or production tooling, we deliver durable, reliable mold tools for every need.

|

Mold Class SPI 105 SPI 104 SPI 103 SPI 102 SPI 101 |

Purpose Prototype Tool Low-volume Production Low-volume Production Medium-volume Production High-volume Production

|

Mold Life Less than 1,000 shots Less than 10,000 shots Less than 50,000 shots Less than 1,000,000 shots More than 1M shots

|

Tolerance +-0.02mm +-0.02mm +-0.02mm +-0.02mm +-0.02mm |

Lead Time 5-7 days 7-10 days 10-15 days 10-16 days 15-25 days |

Material of The Injection Mold

Selecting the right material is crucial for mold longevity and part quality. We offer various material grades for different development stages. Our experts choose the appropriate materials for the required precision and aesthetics and provide professional advice on mold materials.